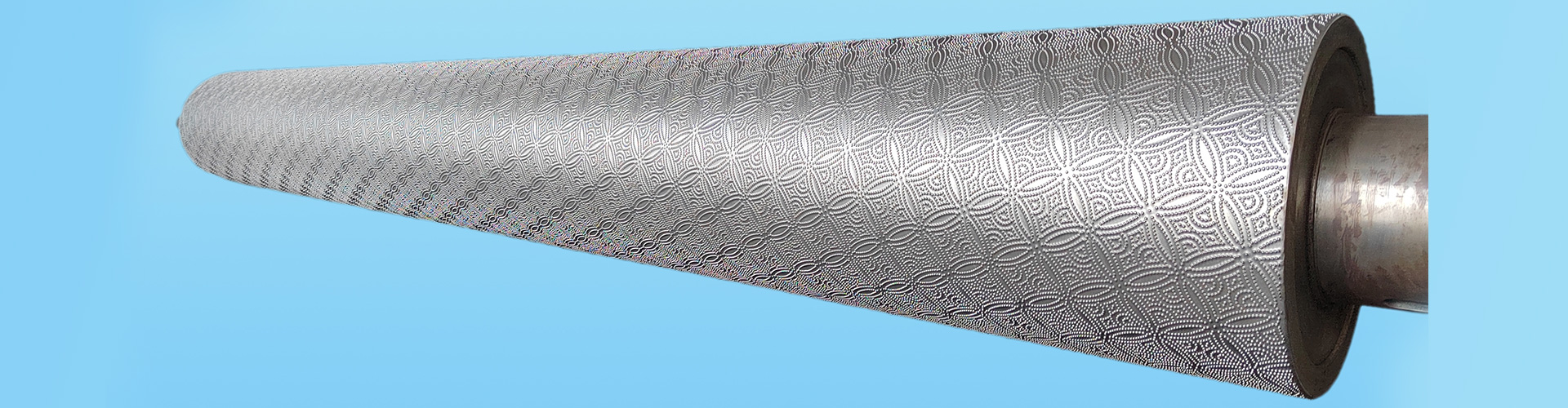

The production process of paper-burning embossing roller is a process of technological production, which not only involves the exquisite skills of technology, but also has relevant professionals. Of course, there should be advanced production equipment, which is what we usually call advanced technology and exquisite technology. It needs to pay attention to many things in the production process, which are the same for the paper embossing roller. Let's take a look at the details.

1. Blanking: seamless steel pipe is used for roller body, 45 round steel is used for shaft, Q235 steel plate is used for end plate, and 8mm machining allowance is reserved according to the drawing size.

2. Turning: turning the joint surface of the matching parts of the roller body, end plate and shaft, etc., according to the H9 / F9 matching precision.

3. Weld the reinforcing rib and shaft at both ends of the combined roller, pay attention to the coaxiality between the shafts at both ends and the inner sleeve, and only weld the inner end plate on the shaft.

4. Install the inner sleeve with complete combination welding into the roller body, and weld the joint of the inner end plate and the roller body.

5. Install the outer end plate on the shaft at both ends and weld the junction of the outer end plate with the shaft and the roller body.

6. Annealing treatment shall be carried out on the blank of welding combination roller to eliminate internal stress. The paper embossing roller is produced in large quantities in our factory.

7. One end of the steel roller shaft shall be flattened and the standard center hole shall be drilled. Professional supplier of embossing roller, please contact our company.

8. Turning: rough and finish turning of each part of the steel roller body to the size required by the drawing. The roughness of the working surface of the roller body shall not be greater than 1.6 μ m; the radial runout tolerance of the working surface of the roller on both ends of the shaft support surface (the installation part of the rolling bearing) is 0.025mm; the roundness of the working surface of the roller body is 0.036 mm; the bearing fitting circle is machined according to K6 precision. Then frame the center frame, turn the end face, and drill to the size. Please contact us if you need the embossing roller.

phone:020-87430805

Mobile phone:13902221452

Fax:020-36521411

address:First floor, Building D, Wanbang Industrial Park, No.6 Caotang Road, Taihe Town, Baiyun District, Guangzhou

020-87430805